timcph2008

Member

Hello guys,

I have some question about modbus simulation between PLC and laptop. However, The PLC and the slave simulator actually not communicated. Would you guys please help me take a look of my configuration? Thank you!

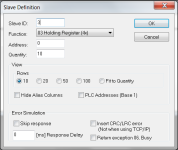

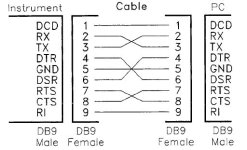

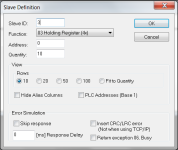

I set PLC as master, use Modbus Slave Simulator from ModbusTools, and configure laptop as number 3 slave. Ideally I want to use RS232 connect laptop and PLC, but I dont have RS232 cable right now, so I use ethernet to serial and serial to USB cable to instead RS232 cable(I dont know is it right to do it.)

I also attach screenshots of configuration of the PLC, Read_VAR, WRITE_VAR function flock, and Slave Simulator.

I have some question about modbus simulation between PLC and laptop. However, The PLC and the slave simulator actually not communicated. Would you guys please help me take a look of my configuration? Thank you!

I set PLC as master, use Modbus Slave Simulator from ModbusTools, and configure laptop as number 3 slave. Ideally I want to use RS232 connect laptop and PLC, but I dont have RS232 cable right now, so I use ethernet to serial and serial to USB cable to instead RS232 cable(I dont know is it right to do it.)

I also attach screenshots of configuration of the PLC, Read_VAR, WRITE_VAR function flock, and Slave Simulator.