You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question on Logix5000 Scan Sequence

- Thread starter notredamon

- Start date

widelto

Member

Welcome to the forum.

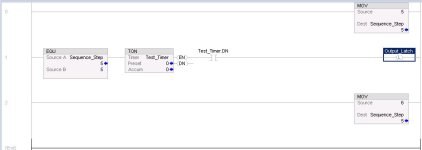

Is the same Output_Latch used in any other part of the program ?

Is the Test_Timer used in any other part of the program ?

Is this routine activated ?

Is the same Output_Latch used in any other part of the program ?

Is the Test_Timer used in any other part of the program ?

Is this routine activated ?

mylespetro

Member

Welcome to the forum.

Is the same Output_Latch used in any other part of the program ?

Is the Test_Timer used in any other part of the program ?

Is this routine activated ?

These are the ones that always get me. Is the rest of the routine definitely running? I often forget to put in the JSR in the routine before it (or in a routine with all JSRs if that's the way the program is built).

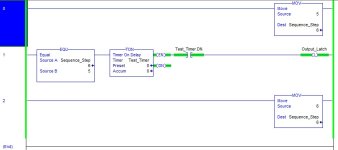

EDIT: Don't know if this is the issue, but you have a 0 in the preset of the timer, not sure if that would just instantly be considered "DONE" or if it just won't work. Try putting an actual value in there.

Ken Roach

Lifetime Supporting Member + Moderator

Welcome to the PLCTalk Forum community. I like your username, I have family and friends who went to ND Maryland, if that's the reference.

One reason that a similar rung would not turn on that bit is that the .EN and .DN output bits are mutually exclusive. Once a Timer is Done, the Enable bit turns off.

The other reason is that a timer always requires at least two scans of the PLC program to complete.

On every scan after the Timer is enabled, the operating system compares the elapsed number of CPU clock cycles to the Preset in milliseconds. If the accumulated time is equal to or greater than the preset, the .DN bit is set.

But if the Preset is zero, the operating system doesn't evaluate the accumulated time instantaneously and set the .DN bit on the very next instruction.

Because your sequencer increments the Sequence Step on the very next rung, the Timer is disabled on the next scan, and never compares its accumulated cycles to the Preset.

One reason that a similar rung would not turn on that bit is that the .EN and .DN output bits are mutually exclusive. Once a Timer is Done, the Enable bit turns off.

The other reason is that a timer always requires at least two scans of the PLC program to complete.

On every scan after the Timer is enabled, the operating system compares the elapsed number of CPU clock cycles to the Preset in milliseconds. If the accumulated time is equal to or greater than the preset, the .DN bit is set.

But if the Preset is zero, the operating system doesn't evaluate the accumulated time instantaneously and set the .DN bit on the very next instruction.

Because your sequencer increments the Sequence Step on the very next rung, the Timer is disabled on the next scan, and never compares its accumulated cycles to the Preset.

Phrog30

Member

The other reason is that a timer always requires at least two scans of the PLC program to complete.

Unless you put two timers in series with the same address. Then it will update in the same scan. We use this when it's important to get a DN bit the same scan with a zero preset. PlantPax uses this "trick" a lot.

notredamon

Member

OP

One reason that a similar rung would not turn on that bit is that the .EN and .DN output bits are mutually exclusive. Once a Timer is Done, the Enable bit turns off.

The other reason is that a timer always requires at least two scans of the PLC program to complete.

Thanks much for explaining this!

Ken Roach

Lifetime Supporting Member + Moderator

We use this when it's important to get a DN bit the same scan with a zero preset

OK, now you've got me curious.

What possible reason could you have for needing to get a .DN bit output from a Timer instruction in the same scan, without a measurable amount of elapsed time ?

That's literally an identity function, 1=1.

My guess is that "because we need to account for times when the preset is zero and don't want a branch where we use "EQU TimerTag.PRE 0".

After studying the logic I thought the output bit should latch, so I loaded it into my Trusty Logix controller and lo and behold it does.

Makes sense to me. As soon as the controller goes into run mode it loads the 5 with the move and the done bit is true at the same time the timer is enabled.

This latches on the output and then moves the 6 into the Sequence_Step tag.

Makes sense to me. As soon as the controller goes into run mode it loads the 5 with the move and the done bit is true at the same time the timer is enabled.

This latches on the output and then moves the 6 into the Sequence_Step tag.

bernie_carlton

Lifetime Supporting Member + Moderator

Ken, don't you mean that .TT and .DN are mutually exclusive?

OkiePC

Lifetime Supporting Member

The TON instruction in and of itself does not have a rung out condition, so the next in series instruction is executed even though it "looks like" the line is attached to the EN bit.

I suspected that the rung should evaluate true all the way across, but don't have hardware to test it.

I suspected that the rung should evaluate true all the way across, but don't have hardware to test it.

Ken Roach

Lifetime Supporting Member + Moderator

Can I go back and delete that post in embarrassment ? Nah, better to leave it up as learning experience.

This specific code doesn't make a lot of sense, but I mis-thought a basic principle: the .EN stays on any time the instruction is true. .TT and .DN are mutually exclusive, but .EN and .DN are both true if the instruction stays true and the elapsed time completes.

Because the first instruction moves a 5 into the Sequencer, the middle rung is true every time it executes, so the timer does complete, because it scans more than once.

Moral of the story: If someone shows you code that doesn't work the way they expect, run it in a controller to be sure your assumptions are right.

This specific code doesn't make a lot of sense, but I mis-thought a basic principle: the .EN stays on any time the instruction is true. .TT and .DN are mutually exclusive, but .EN and .DN are both true if the instruction stays true and the elapsed time completes.

Because the first instruction moves a 5 into the Sequencer, the middle rung is true every time it executes, so the timer does complete, because it scans more than once.

Moral of the story: If someone shows you code that doesn't work the way they expect, run it in a controller to be sure your assumptions are right.

AustralIan

Member

Grey power rail when you are online means you aren't calling this routine anywhere in your code.

This hasn't always been the case, older versions would have it always green.

Let us know if calling the routine gets it to work as you (and we) expected.

This hasn't always been the case, older versions would have it always green.

Let us know if calling the routine gets it to work as you (and we) expected.

Looking at the code it does not make any sense to have a timer as 0, if the pre set was put to say 10 then on seq. equals the timer would start but as the next rung increments the seq. number on the next scan the the compare would be false so timer would reset as it is a normal TON. so why have a timer anyway.

Phrog30

Member

My guess is that "because we need to account for times when the preset is zero and don't want a branch where we use "EQU TimerTag.PRE 0".

Exactly. Using a compare would work. If you needed multiple places in the program, using two timers would be better in my opinion, cleaner as well.

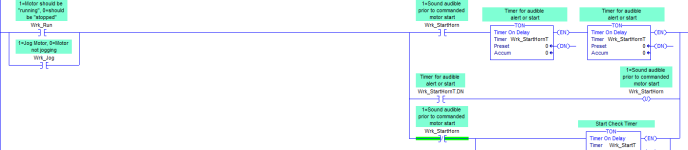

Just one example, a motor AOI with horn timer (horn before start), with zero preset and one timer the horn will blip. With two timers in series and zero preset it will not. Photo from PlantPax.

Similar Topics

Hi all,

I have a PID loop in an AB ControlLogix processor and what I'd like to do is make sure that it doesn't all the CV to fall below a certain...

- Replies

- 3

- Views

- 1,466

So I'm new to the PLC world and just wanting to get some general knowledge. Just a curious question...

How many controllers are in the Logix5000...

- Replies

- 9

- Views

- 2,991

I've got a question for those of you with Ignition experience:

I've been interested in Ignition for a few years now, have not had a chance to use...

- Replies

- 3

- Views

- 1,884

Hi Guys,

I need a few tips here as for something I thought was simple I may be over complicating. I started this and now realise there is a ton...

- Replies

- 30

- Views

- 8,271

I'm sure this is extra simple. I just forgot. How do I remove some accepted edits in logix5000 without deleting other actively accepted edits. I...

- Replies

- 5

- Views

- 3,378