Houdini

Member

I am just new in programming in Logix5000 and Panelview Plus. I've programmed SLC and Panelview classic. I was wondering the best way to tackle my latest project.

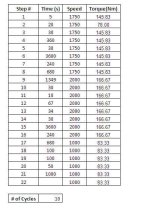

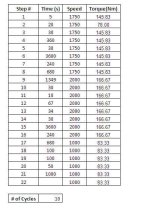

I have a machine that I need to control through various steps. Below I have created a table showing what needs to be done. Bascially it just goes through each step after the timer has reached the setpoint. When it has went through the whole recipe it will go back to the top and continue until it has completed the number of cycles. Sounds pretty easy. I also need a way to edit these values on the panelview Plus. There may also be up to 5 different recipes to choose from.

I have been told to that I can use the Recipe function of the panelview. I have also been told I can use UDT's in Logix to do this. Does this sound like the way to go? Is there an easier way to do this? (I'm also new to UDTs).

The program is already written and working with manually entering the Speed and Torque values So I would just need to tie into those Tags.

Any insight would be great.. Thanks!!

I have a machine that I need to control through various steps. Below I have created a table showing what needs to be done. Bascially it just goes through each step after the timer has reached the setpoint. When it has went through the whole recipe it will go back to the top and continue until it has completed the number of cycles. Sounds pretty easy. I also need a way to edit these values on the panelview Plus. There may also be up to 5 different recipes to choose from.

I have been told to that I can use the Recipe function of the panelview. I have also been told I can use UDT's in Logix to do this. Does this sound like the way to go? Is there an easier way to do this? (I'm also new to UDTs).

The program is already written and working with manually entering the Speed and Torque values So I would just need to tie into those Tags.

Any insight would be great.. Thanks!!

Last edited: