AutomationTechBrian

Lifetime Supporting Member

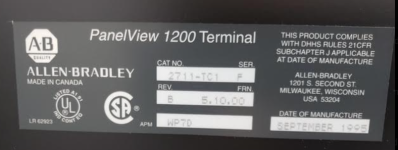

I tried turning this project down, but the panicked look in my customer's face caused me to tell him I will try to come up with a solution... with no promises. But as I get into it, it does seem more possible than my initial impression. Ideally, I would convert the old screen to ether a new, or "newer" HMI (panelview or otherwise). But I don't do this often enough to know from experience which path to take. I have some attachments to share. It's a SLC 5/03, and the PanelView is connected to an RIO Scanner... and they took advantage of the distance capabilities of RIO. The machine and HMI are a couple hundred feet away from the panel with the PLC (see pic of PLC in the panel). The great news is that the original machine builder gave me the original PLC and HMI files. I did some digging on the Rockwell site and found a copy of PanelBuilder 1200 that I downloaded and installed on an Windows XP, SP2 VM. So, I have a printout of all the original screens, and after reading Ken Roach's experience with the conversions, I'm expecting to re-create all the screens from scratch in the new HMI software, without trying to convert this file. It really doesn't seem that complicated of an application.

So... any advice how I could, or should, accomplish a retrofit? Obviously the RIO is a snag. I first thought about a bridge to Ethernet, but the one recommended is long obsolete. I thought about replacing the 5/03 with a 5/05 with Ethernet.... until I Googled it and saw the prices upwards of $9k. It still might be a possibility, but I don't know what I don't know about converting the program from a 5/03 to a 5/05. The screen only needs to be about 10" or so, and it doesn't really have to be a PanelView if something else would work well (and is readily available).

I'll post some pics, and the PLC program. I could also post a PDF of the HMI if it is helpful, but I'd want to edit it first to remove details about the customer. I noticed that pics will often show up without having to open a file if there is only one pic per post, so that's what I'll try doing.

I'm hoping this will work out. My world is full of legacy equipment, and I'd like to better learn how to help some of these folks.

What are your thoughts?

So... any advice how I could, or should, accomplish a retrofit? Obviously the RIO is a snag. I first thought about a bridge to Ethernet, but the one recommended is long obsolete. I thought about replacing the 5/03 with a 5/05 with Ethernet.... until I Googled it and saw the prices upwards of $9k. It still might be a possibility, but I don't know what I don't know about converting the program from a 5/03 to a 5/05. The screen only needs to be about 10" or so, and it doesn't really have to be a PanelView if something else would work well (and is readily available).

I'll post some pics, and the PLC program. I could also post a PDF of the HMI if it is helpful, but I'd want to edit it first to remove details about the customer. I noticed that pics will often show up without having to open a file if there is only one pic per post, so that's what I'll try doing.

I'm hoping this will work out. My world is full of legacy equipment, and I'd like to better learn how to help some of these folks.

What are your thoughts?