arth608

Member

Hello All,

This might be a simple question for most of you. I am working on performing some tests on an EIP device through RSLogix 5000.

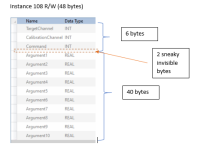

Based on the information from the EDS files, I have created two user-defined data types that would allow me to use MSG instructions and pull data from those assemblies. Assembly 108 is read/write and Assembly 109 is read-only.

My question is in regards to Assembly 108. How to I write by passing the entire assembly through MSG instruction and Set Attribute Single service.

See the attached document for reference.

This might be a simple question for most of you. I am working on performing some tests on an EIP device through RSLogix 5000.

Based on the information from the EDS files, I have created two user-defined data types that would allow me to use MSG instructions and pull data from those assemblies. Assembly 108 is read/write and Assembly 109 is read-only.

My question is in regards to Assembly 108. How to I write by passing the entire assembly through MSG instruction and Set Attribute Single service.

See the attached document for reference.