Hi All,

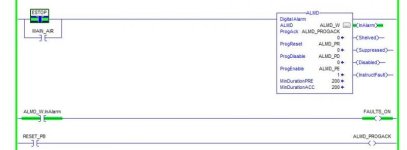

I wonder if anyone knows the answer, or even if its a stupid question, as to whether the ALMA / ALMD blocks that rslogix uses for alarms which can be veiwed on FactoryTalk HMIs / Scada, can also be viewed / used directly as alarms in other manufacturers Hmi's / Scada.

At the moment this is one of the things that is tying us to FactoryTalk, when there are much better / more reliable solutions out there.

Thanks in advanced.

I wonder if anyone knows the answer, or even if its a stupid question, as to whether the ALMA / ALMD blocks that rslogix uses for alarms which can be veiwed on FactoryTalk HMIs / Scada, can also be viewed / used directly as alarms in other manufacturers Hmi's / Scada.

At the moment this is one of the things that is tying us to FactoryTalk, when there are much better / more reliable solutions out there.

Thanks in advanced.