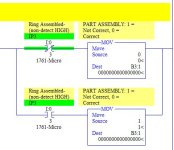

On rung 0007, we need to first verify that a metal part was DETECTED, and also whether a ring was detected at the same time. If it was, put a "0" in our flag B3:1 for a correctly-assembled part, or if not, then put in a "1" for a bad part.

Is there a workaround to correctly identify each logic box descriptions at rung 0007? Each time I edit one the other one follows. I figure it's because they both use the same B3:1.

One other thing is the Ring Chute Jam Alarm mentioned in the instructions. I did not know exactly how to handle that. I put an instruction in Rung 0002 to shut off everything if it triggers. The problem is that we don't know what sensor triggers that alarm. Apparently in the simulator, that is built-in and not part of the ladder program.

I think it's just an extra. At this point the program for what it is has enough supportive content to demonstrate understanding of the simulator in my opinion. This problem is for the Distinction grade understandably.

Cheers.