Hello Everyone, thank you for taking the time to read this post. I got this short program of a Packing Line. I documented everything. I was hoping someone could have a look and point out mistakes and simplified logic advice?

Here is the description:

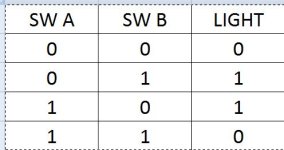

The packing line carries boxes of different sizes that need to be separated at the end of the first conveyor. Which direction the boxes travel at the end of the first conveyor should be decided by using the input sensors IP1 and IP2. If the box is a short one, the inputs will only be energised one at a time. If the box is a long one then, for a short period, both inputs will energise at the same time.

When the box reaches the end of the first conveyor, which is driven by OP0, it will come to rest on the circular plate and will energise the sensor IP3 (the first conveyor will also stop). The plate will then turn either to the left or the right depending on the length of the box. OP2 turns the plate to the right; OP1 turns the plate to the left.

Once the plate has turned, the box will be pushed on to the next conveyor by either piston OP4 or OP3. Output OP6 drives the left-hand conveyor and output OP5 drives the vertical conveyor. Inputs IP4 and IP5 are sensors which detect the boxes on the conveyors as they are transported to the correct loading areas depending on their length.Once the boxes pass these sensors there should be a short delay and the respective conveyor should stop.

Write a program to carry out the previously described operation and, as with the previous assignments, use the documentation facilities. When the program is complete, test its operation using the simulation package. To use the graphic simulation click on a box which, will place the selected box on to the first conveyor then operate the start switch IP0.

Program in attachment.

Much Appreciated,

Cheers! :site:

Here is the description:

The packing line carries boxes of different sizes that need to be separated at the end of the first conveyor. Which direction the boxes travel at the end of the first conveyor should be decided by using the input sensors IP1 and IP2. If the box is a short one, the inputs will only be energised one at a time. If the box is a long one then, for a short period, both inputs will energise at the same time.

When the box reaches the end of the first conveyor, which is driven by OP0, it will come to rest on the circular plate and will energise the sensor IP3 (the first conveyor will also stop). The plate will then turn either to the left or the right depending on the length of the box. OP2 turns the plate to the right; OP1 turns the plate to the left.

Once the plate has turned, the box will be pushed on to the next conveyor by either piston OP4 or OP3. Output OP6 drives the left-hand conveyor and output OP5 drives the vertical conveyor. Inputs IP4 and IP5 are sensors which detect the boxes on the conveyors as they are transported to the correct loading areas depending on their length.Once the boxes pass these sensors there should be a short delay and the respective conveyor should stop.

Write a program to carry out the previously described operation and, as with the previous assignments, use the documentation facilities. When the program is complete, test its operation using the simulation package. To use the graphic simulation click on a box which, will place the selected box on to the first conveyor then operate the start switch IP0.

Program in attachment.

Much Appreciated,

Cheers! :site: