auto123

Member

Hello,

I am new to plc programming. I am trying to program a flow meter (E&H promag 50) in somachine basic to achieve the following:

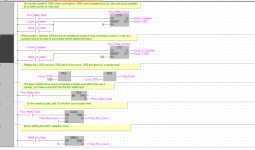

1. Trigger an output when a certain amount of liquid has passed through a pipe. For this, I've tried a positive edge detection input with an up-counter but the number of pulses required (amount of liquid) is higher than the preset value of the counter.

2. obtain a flow totaliser

Can someone explain how to do the programming in somachine basic?

I am new to plc programming. I am trying to program a flow meter (E&H promag 50) in somachine basic to achieve the following:

1. Trigger an output when a certain amount of liquid has passed through a pipe. For this, I've tried a positive edge detection input with an up-counter but the number of pulses required (amount of liquid) is higher than the preset value of the counter.

2. obtain a flow totaliser

Can someone explain how to do the programming in somachine basic?