Welcome to the PLCTalk forum community !

When you ask for an equipment recommendation, you're going to get quite a lot of people recommending their favorites, which are often the ones they're most comfortable with because of their experience. What sort of languages and controllers do *you* have experience with ?

I happen to agree with the Red Lion suggestion at first blush, but want to ask some questions and give some additional input.

I recently did an application using a barcode reader and an Allen-Bradley PanelView Plus. I ran into a couple of hiccups that made it less smooth and I would like so I looked up some videos and technotes about doing the same thing with Red Lion. To my surprise, their barcode input methods had specifically addressed two of the problems I had; input object focus and enter key delay.

It sounds like you have a 2-D symbol reader of some kind, probably with a USB connection. What exact model, and what kind of symbols are you reading ?

Do your employees have to enter their Employee Number on a keyboard or touchscreen, or do you want to scan an employee ID badge with that 2-D reader, or have employees swipe an ID card through an RF proximity reader ?

Where does the SQL server live; do you have an enterprise SQL server with tables you've already set up that accepts remote queries and commands ? Is it Microsoft SQL Server, or something else ?

Do you want to have a dedicated HMI touchscreen, or would a browser-based HMI that the operators can open on that Windows workstation be more convenient ? Some Red Lion HMIs have a "virtual HMI" feature, and some are entirely headless (the DataStation and FlexEdge).

Red Lion has a few SQL-related features but not an extensive feature set. It's largely limited to SQL Sync, which does bulk upload of log files into an SQL Server, and SQL Query, which only does SELECT commands to pull data from an SQL server and put it into Red Lion tags. It does not do UPDATE or INSERT, which it sounds like you need. You can have a look at seeing if you can log the data you want, then set up SQL Sync to basically grab batches of it and put it into the SQL Server.

What source do you have for an accurate Time value to your automation system ? Would the workstations and SQL server, and/or the automation device you select, have sufficient access to the Internet to query the time from pool.ntp.org ? Or do you have a server or gateway or other device in your system that you rely on to keep time ?

What do you intend to do with this logged data about the parts ?

What other sorts of processes and equipment do you anticipate adding automation to ?

Hi Ken,

First thanks for taking the time to ask such relevant questions.

Experience - My background is CNC machines. I've been repairing CNC machines (Matsurra, Okuma, Haas, DMG Mori, Makino, and a few others) for about 10 years. Most of that experience did not include getting into ladder logic or the back end of the machine programs. To answer your question about experience with regard to PLC programming, the answer is next to none. I was able to setup communication between my PC to Delta PLC and HMI. I was able to program one logic instruction to turn on a lamp with a button on the HMI. I have no clue about the meaning of bits / bytes / registers, internal memory, internal parameter, or tags.

Code Scanners - We currently have various handheld and fixed models from Keyence - SR-700HA, SR-X100W, HR-X100, HR-X100WB, BT-A500GA. We also have various Amazon specials, a Honeywell Granit 1981i, but I'm looking at COGNEX products for future installations.

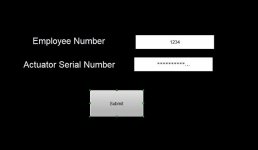

Employee ID - We currently have to type in our ID number to data collections applications. I would however prefer the RF prox reader.

SQL - I'm not sure of the exact details, but we do have at least one SQL Server running for our MRP / CRM / ERP software (Epicor). Our IT department is difficult on a good day to interact with so I'm looking at a Cloud based SQL service. I do have a LAMP stack running Turnkey Linux with MariaDB and Adminer web interface. I have no preference and if a local instance is best I can make it happen.

Operator Interaction - My vision was a dedicated HMI touchscreen at each work station, but a browser-based HMI sound interesting and I'd like to learn more. One of the complaints from operators is the windows lock after 15 min which is a restriction I can't over come. For that reason a dedicated HMI "sounded better".

SQL Sync - That sounds like an extra layer of complexity that might not be helpful at this stage of my learning / project implementation.

Time - All systems have access to the internet. I can check with IT about local options for referencing accurate time.

Logged Data - My vision is to create production graphs, charts, SPC, PFMEA, training matrix, and real time factory floor overviews.

Future Systems - After a successful proof of concept with this first simple project, my goal is to roll out very similar installations to our full assembly lines. After that I would like to incorporate this model to collecting work in progress data at machining work centers, and in-process inspection data. After that I'd like to work on a building automation project that would help maintain our electrical, HVAC, plant air, access control and security systems.

I'm sure I missed a lot of information, but I think this is a good start. If you would like to check out our company, please visit

Competitive Engineering And just to be clear, I did not have anything to do with the creation of that website. The images are dated and we have since replaced about 14MM of capital equipment in the past 4 years.