FischerPLC

Member

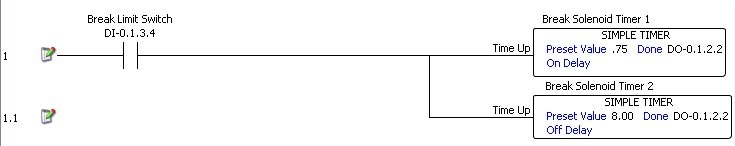

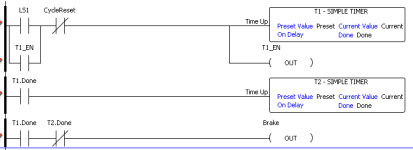

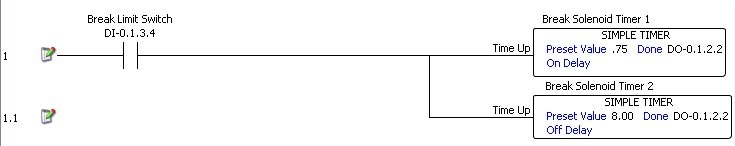

i have an instance where a limit switch activates a solenoid. My issue is that my on timer only works so long as the limit switch is held down, or the bit is active. If the limit switch is released it activates instantly. The limit switch is pressed for about a tenth of a second. I'm thinking this is a software issue.

my attached image is the closest I've came. originally it was a debounce coil set to turn off after 8 seconds (i don't know why he used debounce).

also I'm guessing that in order to help me you'll need to know the software (Productivity Suite).

my attached image is the closest I've came. originally it was a debounce coil set to turn off after 8 seconds (i don't know why he used debounce).

also I'm guessing that in order to help me you'll need to know the software (Productivity Suite).