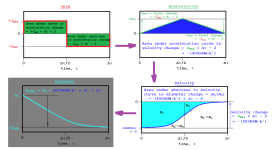

Hi all. First time programming a machine of this type. A center driven unwind feeding to a center driven rewind. No dancers or load cells, just used to pull coiled metal off of a core. I have laser diameter sensors on each roll, so calculating speed based on circumference is easy enough. Where Im getting hung up is the math behind getting the machine to decelerate so that we end up with the same diameter roll on the rewind as we started with on the unwind, minus the core thickness. I would like for the machine to reach a certain point then start to decelerate until it reaches the finished roll size. Any suggestions?

I read up on distance to stop formulas and jerk rates and what not but got lost quickly. Linear distance of material doesn't really matter here, since Im just pulling material off of a core and winding it back up sans core. I think we can do it based on roll diameter minus core thickness just unsure how.

The unwind/rewind shafts only spin at a maximum 400 rpm, accel/decel rates will be operator inputs, but assume pretty slow.

I read up on distance to stop formulas and jerk rates and what not but got lost quickly. Linear distance of material doesn't really matter here, since Im just pulling material off of a core and winding it back up sans core. I think we can do it based on roll diameter minus core thickness just unsure how.

The unwind/rewind shafts only spin at a maximum 400 rpm, accel/decel rates will be operator inputs, but assume pretty slow.