The third-grader solution of the task imagined by me (the scheme is attached)

(the task is simplified as much as possible, to understand the approach to the solution, or I'm just too lazy to solve)

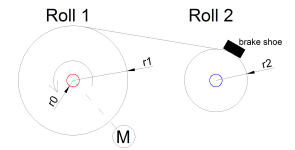

R is the radius of the roll of all material wound on the shaft

r0 - shafts radii

r1, r2 are the radii of rolls 1 and 2 at some point in time

w1, w2 are the angular velocities of rolls 1 and 2 at some point in time

h - material thickness

p is the density of the material and shafts

L - width of material and shafts

J - torque

E - rotational energy

F - friction force

J = (m * r^2) / 2 - solid cylinder

E = (J * w^2) / 2 = (m * r^2 * w^2) / 4 = (p*L*pi*r^2 * r^2 * w^2) / 4 = (p *L*pi* r^4 * w^2) / 4

Total rotational energy of the system

E = p*L*pi* (r1^4 * w1^2 + r2^4 * w2^2) / 4

w2 = w1 * r1 / r2

E = p*L*pi* (r1^4 * w1^2 + r2^4 * (w1 * r1 / r2)^2) / 4 = p*L*pi* (r1^4 * w1^2 + r2 ^2 * w1^2 * r1^2) / 4

r2^2 = R^2 + r0^2 – r1^2

E = p*L*pi* (r1^4 * w1^2 + (R^2 + r0^2 – r1^2) * w1^2 * r1^2) / 4

Find the radius of the roll 1 r1 at which it is necessary to apply a brake shoe to create a constant friction force F

E = F * l = F * pi * (R^2 – r1^2) / h

E=E

p*L*pi* (r1^4 * w1^2 + (R^2 + r0^2 – r1^2) * w1^2 * r1^2) / 4 = F * pi * (R^2 – r1 ^2) / h

p*L* (r1^4 * w1^2 + (R^2 + r0^2 – r1^2) * w1^2 * r1^2) / 4 – F * (R^2 – r1^2) / h = 0

(p*L*(R^2 + r0^2) * w1^2 / (4*F) + 1 / h) * r1^2 – R^2 / h = 0

r1 = R/ (h*p*L*(R^2 + r0^2) * w1^2 / (4*F) + 1)^0.5

At the moment when the roll 1 radius becomes = calculated r1, you need to turn off the drive and apply a brake shoe with friction force F

Linear increase in friction force from 0 to 2* F followed by a linear decrease to 0

l * h = pi * (R^2 – r1^2)

0.5 * l * h = pi * (R^2 – r1x^2)

0.5 * (R^2 – r1^2) = (R^2 – r1x^2)

r1x = (0.5 * (R^2 + r1^2))^0.5

If

Measured roll radius 1 > r1

Then

If

Measured roll radius 1 < r1x

Then

Target braking force = (Measured roll radius 1 - r1) / (r1x –r1) * 2* F

Else

Target braking force = (R - Measured roll radius 1) / (R -r1x) * 2* F

End if

End if