jay7880

Member

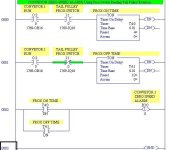

I'm doing a sand silo system at a foundry..an outside company has provided the control cabinet and programming...the conveyors normally have zero speed switches on the tail end but most are missing or broken...I do have proximity switches that are the same style as what the foundry season all their other conveyors...what can I do to replace with the proximity switches? Have the programming changed to make them a time delay switch and to close a contact in the plc to sound an alarm it the set time expires or can I simply use them in the same way as a zero speed switch

![DSC00792[1].JPG DSC00792[1].JPG](https://www.plctalk.net/data/attachments/30/30965-8bc3d2709972c9c12fef33f053c0bf89.jpg)