Hi, hope someone could enlighten me on this issue

I had that happen only twice in 2 years of operation of that particular program so its very rare (at least to detect). Here is what happened:

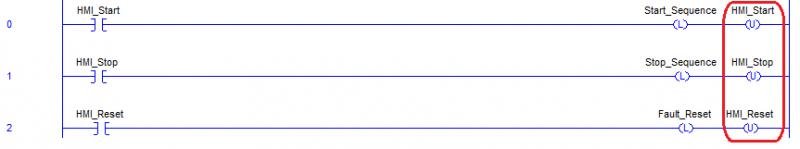

I was called to situation in which particular machinery was not able to start. After troubleshooting on line for a while I found that the momentary STOP button from one of the HMI screens was showing active in the PLC program. All what I had to do to "fix" it - was to toggle status inside PLC ladder logic.

Here are the other relevant details: PLC are interacting with number of redundant HMI's (running same Factory Talk View application on Windows based touchscreens) through HMI server on Industrial Ethernet network. At both instances that happen years apart I was able to toggle status from the PLC program which would imply that there was nothing wrong with HMI's, but rather it is related to the way and frequency (if any) this status is refreshed. Each time it was completely different switch and Page of application (two different machinery was controlled from same HMI).

At first time it happen, when I report it to my Engineering Department - I was told that AB is aware of "glitch from HMI", they call it "stuck key anomaly". However I was never forced to follow on it since there was no reoccurrence till now.

If anyone knows any official details from AB on that issue and forward it to me I would be very thankful

Cheers

I had that happen only twice in 2 years of operation of that particular program so its very rare (at least to detect). Here is what happened:

I was called to situation in which particular machinery was not able to start. After troubleshooting on line for a while I found that the momentary STOP button from one of the HMI screens was showing active in the PLC program. All what I had to do to "fix" it - was to toggle status inside PLC ladder logic.

Here are the other relevant details: PLC are interacting with number of redundant HMI's (running same Factory Talk View application on Windows based touchscreens) through HMI server on Industrial Ethernet network. At both instances that happen years apart I was able to toggle status from the PLC program which would imply that there was nothing wrong with HMI's, but rather it is related to the way and frequency (if any) this status is refreshed. Each time it was completely different switch and Page of application (two different machinery was controlled from same HMI).

At first time it happen, when I report it to my Engineering Department - I was told that AB is aware of "glitch from HMI", they call it "stuck key anomaly". However I was never forced to follow on it since there was no reoccurrence till now.

If anyone knows any official details from AB on that issue and forward it to me I would be very thankful

Cheers