Foxtrot2050

Member

Good morning crew!

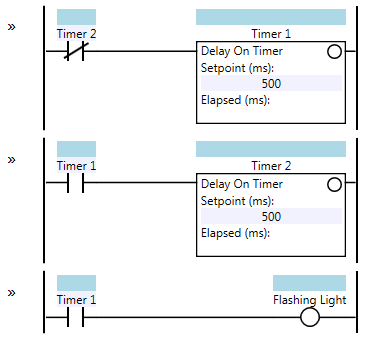

Ok my logic works but I am missing something. When the start button is pushed it should like the red light for 4sec then shut off. When the red light shuts off the green light is supposed to come on for 3 sec then shut off which triggers the red light to auto reset. This happens 5 times then shuts everything off. This all works but I am not sure how to shut off the red light without it ruining the whole system. I know I am close.

Part 2 = Once I get this working in Ladder Logic I need to make this into a function block program in Studio 5000. Any assistance would be great, I am still learning a lot about function block programming.

Thanks for any help I can get!

Ok my logic works but I am missing something. When the start button is pushed it should like the red light for 4sec then shut off. When the red light shuts off the green light is supposed to come on for 3 sec then shut off which triggers the red light to auto reset. This happens 5 times then shuts everything off. This all works but I am not sure how to shut off the red light without it ruining the whole system. I know I am close.

Part 2 = Once I get this working in Ladder Logic I need to make this into a function block program in Studio 5000. Any assistance would be great, I am still learning a lot about function block programming.

Thanks for any help I can get!