kf4sqb

Member

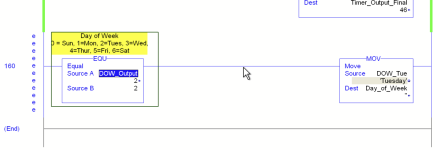

First off, I'm a hobbyist-level programmer, and this program isn't controlling anything anything that could even remotely be considered "life safety". I'm using RSLogix 5000 (full edition, version V20.01.00 (CPR 9 SR 5), with a 1768-L45 CompactLogix 5345 PLC. I've just added a couple of new rungs in on-line edit, and they continuously show an "e" beside the new rungs. I know that this means there is an error on the rung, but I don't see what the issue is, and I get nothing when I try to use the "verify rung" function by right-clicking on the rung number and selecting it from the context menu. When I hover the mouse cursor over the "verify rung" selection in the context menu, it shows "verify the rung the caret is on" in the lower left, but once I click on it, it simply shows "ready" in the lower left. What am I missing? Is there a setting I need to check to ensure this feature is supposed to be working? I am using the software in a virtual machine, so it could possibly be a settings issue with the VM simply not showing the portion of the "screen" the error details should be on, but I seem to recall it usually showing up in the lower left corner of the screen, where normally says "ready" if nothing is selected, or tells you what should be there if you select an instruction/part of an instruction ("enter source a operand or value"). Here's a screenshot of the rung in question:

Here, "DOW_Output" is an interger representing the day of the week, and is a DINT data type, while "DOW_Tue" is a constant string tag, simply containing the word "Tuesday", and "Day_of_Week" is a string tag (NOT constant). I'm setting this up to be able to display the day of the week on an HMI. I know there are other ways to do this, but I'd really like to get this setup working, more as a learning experience than anything else. Also, this is my first time working with string tags, so it's very possible that I don't properly understand how to work with them. I'd really like to understand why the "verify" function isn't telling me anything, but does anyone see what's wrong with this rung?

Here, "DOW_Output" is an interger representing the day of the week, and is a DINT data type, while "DOW_Tue" is a constant string tag, simply containing the word "Tuesday", and "Day_of_Week" is a string tag (NOT constant). I'm setting this up to be able to display the day of the week on an HMI. I know there are other ways to do this, but I'd really like to get this setup working, more as a learning experience than anything else. Also, this is my first time working with string tags, so it's very possible that I don't properly understand how to work with them. I'd really like to understand why the "verify" function isn't telling me anything, but does anyone see what's wrong with this rung?