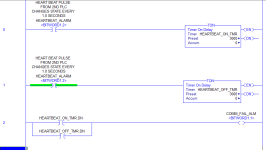

Send a heart beat from one PLC to the other over the network - say a 1 second pulse - 50% on and 50% off. At the other end have a timer that is reset by the pulse - if the timer times out there is trouble.

I have utilised this in the old days with great success - these days my PLC of choice has heaps of options in monitoring bits for mode (run or not), in the data link, not in the data link, active or inactive - you name it. For comms failure for example I use the in data link bit - pull out an Ethernet cable, program mode, fail or whatever and the bit turns off - really simple to use.

I have utilised this in the old days with great success - these days my PLC of choice has heaps of options in monitoring bits for mode (run or not), in the data link, not in the data link, active or inactive - you name it. For comms failure for example I use the in data link bit - pull out an Ethernet cable, program mode, fail or whatever and the bit turns off - really simple to use.