MATT116

Member

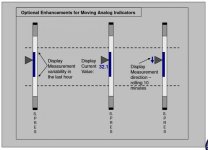

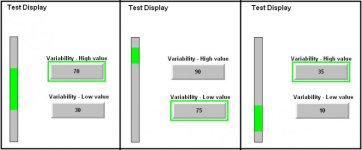

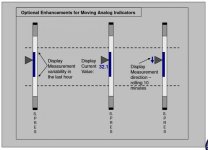

Have a customer wanting the ability to show the "Measurement variability in the last hour" (see pic).

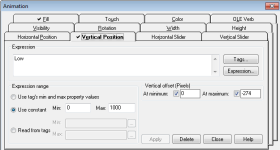

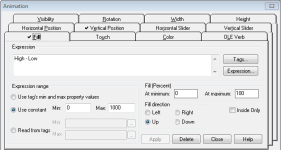

I can handle generating the variability in the PLC just not sure what to use on the HMI to show the variability. I've been playing with a Polygon and the Vertical Position & Fill but just not getting the desired results. Any ideas?

Studio 5000 V24

PVPlus 6 15" & FTView ME V8.1

I can handle generating the variability in the PLC just not sure what to use on the HMI to show the variability. I've been playing with a Polygon and the Vertical Position & Fill but just not getting the desired results. Any ideas?

Studio 5000 V24

PVPlus 6 15" & FTView ME V8.1