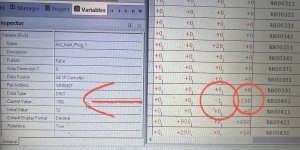

Start with a value of 65537 in a DINT variable in the PLC. In the PLC, that DINT will use two consecutive %R addresses. If you open a reference view table in PME and look at the %R address, you'll see a value of 1 each of the two %R addresses involved. Now right click on the first %R address, select "Format View Table" and select DWORD as the format. You'll see the value is now 65537. Now write that DINT to the CSV file and see what value you get. If it's 65537, the script wrote a DINT, if it's 1, the script wrote an INT.

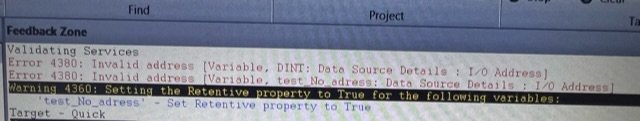

I sent Emerson an email and received this as a response.

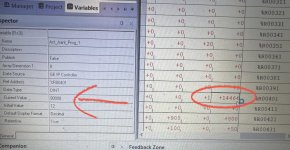

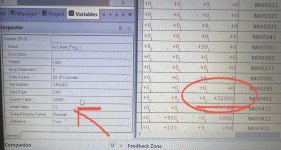

Look at the registers next to R2429 (i.e. R2430 or R2428). It can be R2429 + R2430 or R2428 + R2429.

These registers are 16bit. System uses 2 of these registers to create a DINT (32bit).

So you have to use 2 registers in the script. Then make a calculation to get the correct value.

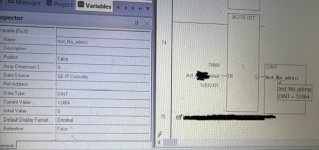

So I can't manage that last part that needs to be in the script. is there anyone who can help me with this? So I have the existing script in it, the part:

So you have to use 2 registers in the script. Then make a calculation to get the correct value.

I can create and write the tags that belong in by myself if I have only 1 example sentence/script.