MorphuisOGrady

Member

Hi Guys,

I need a few tips here as for something I thought was simple I may be over complicating. I started this and now realise there is a ton if if statements required to get this right.

Logix5000,FTView SE

I have 6 PLC controlled machines that I want the ability to pair as required from HMI.

Logix5000, FTView SE

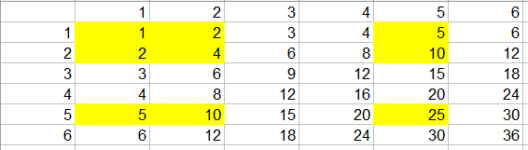

Feed Mac1 Mac2 Mac3 Mac 4 Mac5 Mac6

Machine 1 1 1 1 0 0 0

Machine 2

Machine 3

Machine 4

Machine 5

Machine 6

Machine 7

Each machine has a Machinex_Media_Word tag of type Int. In the first selection row I have paired 1,2 and 3 so they will share the same feed resources.

If I set the respective bits in the INT through radio buttons on HMI how do I get it to copy down through each word ensuring that there are no invalid selections?

In other words if Machine1, Machine2 and Machine 3 are paired they will share the same resources, so on the next line Machine 2 should automatically be 111000.

Does this make sense?

I need a few tips here as for something I thought was simple I may be over complicating. I started this and now realise there is a ton if if statements required to get this right.

Logix5000,FTView SE

I have 6 PLC controlled machines that I want the ability to pair as required from HMI.

Logix5000, FTView SE

Feed Mac1 Mac2 Mac3 Mac 4 Mac5 Mac6

Machine 1 1 1 1 0 0 0

Machine 2

Machine 3

Machine 4

Machine 5

Machine 6

Machine 7

Each machine has a Machinex_Media_Word tag of type Int. In the first selection row I have paired 1,2 and 3 so they will share the same feed resources.

If I set the respective bits in the INT through radio buttons on HMI how do I get it to copy down through each word ensuring that there are no invalid selections?

In other words if Machine1, Machine2 and Machine 3 are paired they will share the same resources, so on the next line Machine 2 should automatically be 111000.

Does this make sense?