caution! philosophy ahead ...

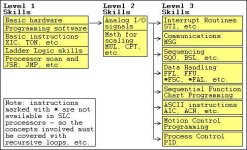

Concerning the general thrust of this thread - it seems like a lot of people ask this same type of question. Even if this little flow chart can’t offer a quick solution - maybe it will at least help define the problem.

[attachment]

The way I see it, a “raw recruit” to the PLC world needs to gain at LEAST the basic abilities which are blocked together under the title “Level 1 Skills”. Specifically, he (or she) MUST have at least a basic understanding of how the PLC hardware fits together - he MUST be able to work on a least a fundamental level with the programming software - he MUST understand the operation of the basic program instructions (such as Examine On, Examine Off, Timers, Counters, etc.) - he MUST have at least a fundamental understanding of how to interpret Ladder Logic programs - and he MUST have at least a basic understanding of how the processor scans and executes the program. If any one of these skills are neglected, then the technician’s effectiveness on the job will be significantly diminished.

Sooner or later the items listed under Level 2 Skills are required of almost every PLC technician. These are the skills associated with analog inputs and outputs. To most students the skills involved in handling these types of signals are significantly different from the “press a button - make a pump run” type of exercises they learned in Level 1 classes. Now the signals are no longer just ones and zeros - they are numbers which range in value from 0 to 4095 - or from 3277 to 16384 - or from 6242 to 31208 - and so on - and so on - and so on. Now the student needs to have his basic math skills in place - these raw signals need to be scaled and converted into temperatures, flow rates, etc. Further, if the platform happens to be an Allen-Bradley PLC-5, then the topic of block transfers rears its ugly head.

Next after analog signals, we come to what most students would consider “advanced programming” skills. Personally, I discourage that term. Secret handshake: The skills in this level are no more “advanced” - nor are they any more difficult to learn - than all of the material which the student has already covered. It’s pretty much like brain surgery - or tying your shoe. Once you UNDERSTAND something (anything) - then you can always look back and say, “Well, that wasn’t so hard after all.” The problem of course lies in gaining that all-important level of understanding. At least that’s my own personal philosophy. Anyway -

Notice that each “block” in the Level 3 Skills category is separated from the others - and represents a separate path. To my way of thinking, once a student has gotten Levels 1 and 2 under his belt - then it’s time to “pick a major” as they say in college. Hopefully the “raw recruit” we started out with in Level 1 has by this time gotten a job working with (or at least around) PLC’s. If so, then the employer is likely to pick the path which the student is required to follow. Simply put - some plants have absolutely NO use for some of these topics - while other plants may DEMAND them. It’s mostly dictated by the type of plant - and by the type of equipment which is being controlled. It would be a good idea to ask around before wading into any one of these particular topics. Don’t get me wrong - ANY knowledge is a good thing - but there is the potential for “wasting” a lot of misdirected time by learning skills which you might NEVER need. As in all areas of life, try to choose your path wisely.

Finally, in putting this down on paper, I tried to arrange the topics under Level 3 Skills in order of increasing complexity. In other words, I personally consider the topic of “Interrupt Routines” to be much easier to learn (certainly it requires much less time) than PID for “Process Control”. I’m sure that some of the “big dogs” on this forum would disagree with this order - and perhaps they will offer new ideas as to how I might improve my little flow chart. As always, I’m open to suggestions.

Anyway - for what it’s worth - that’s the way I see it.