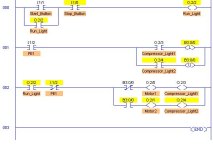

logix pro dual compressor exercise

- Thread starter ijr900

- Start date

Similar Topics

How can I convert psi reading on pressure tank to bcd ?

So, I have a little dillemma I am trying to work through but I feel there is probably a better way. I've always liked the idea of using a VM in...

I have some software that requires the use of rslogix 5 professional (Auvesey Octohub) But now that Rockwell no longer offers Pro licensees I am a...

I want transfer my I/O data from schneider (Unity Pro) as a write data and RS Logix 5000 as a read data. I use Ethernet as an communication...

I am trying to move an RS5000 21.03.01 install on a Win10Pro machine. Currently have this existing setup on another Win10Pro machine. The only...