neokeelo

Member

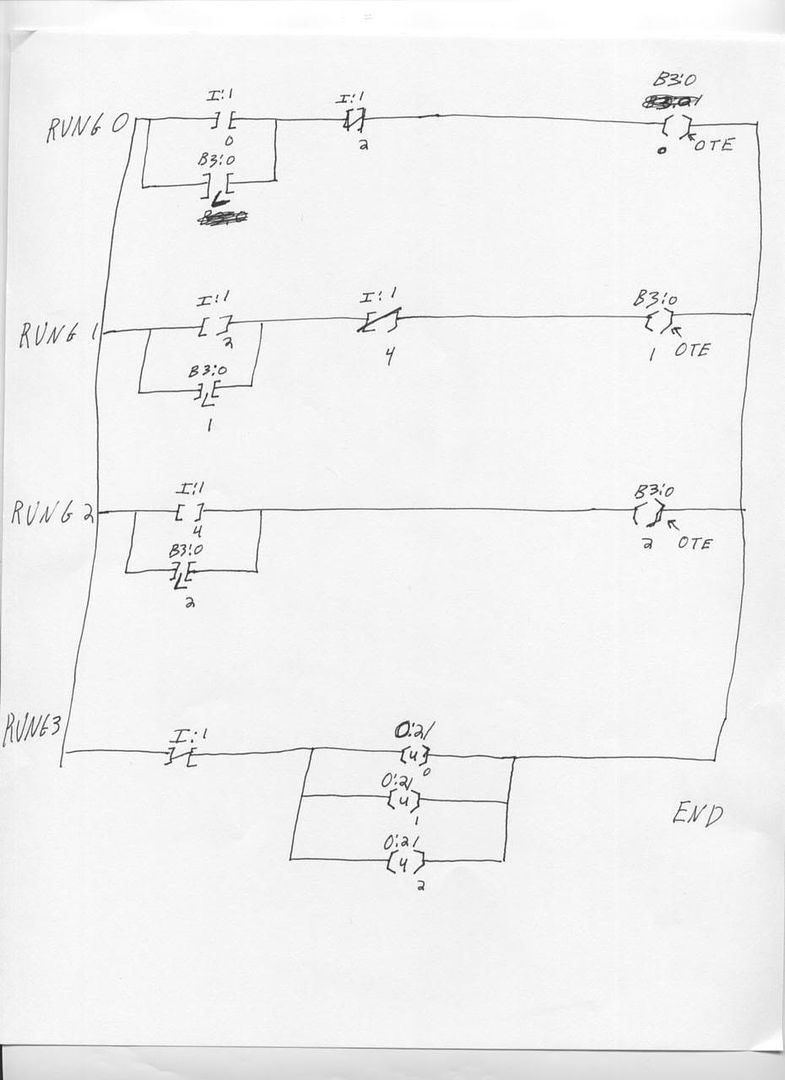

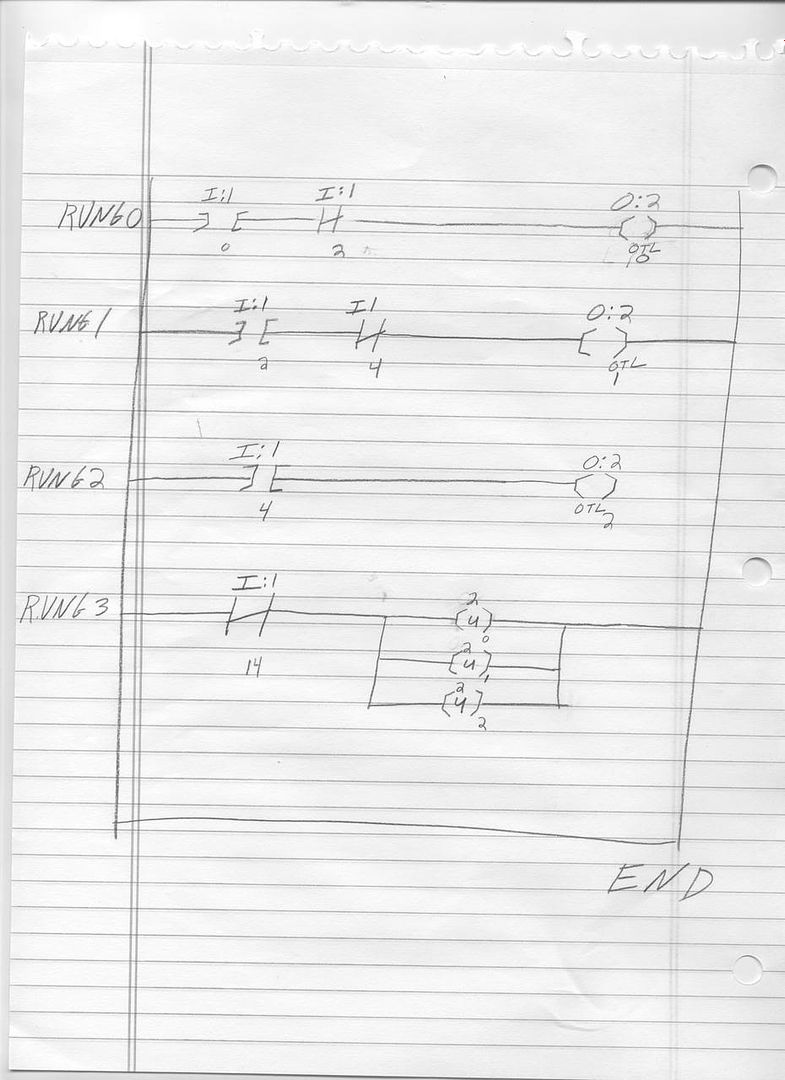

Hello. I am very new into PLC and am still learning basic logic and the commands using the LogixPro 500 software. My teacher assigned us a homework assignment and I am stuck with this problem. He didn't really give us many examples so I'm trying to learn how to make the program. Could anyone help me with the last line?

Here is the Assignment

------------------------------

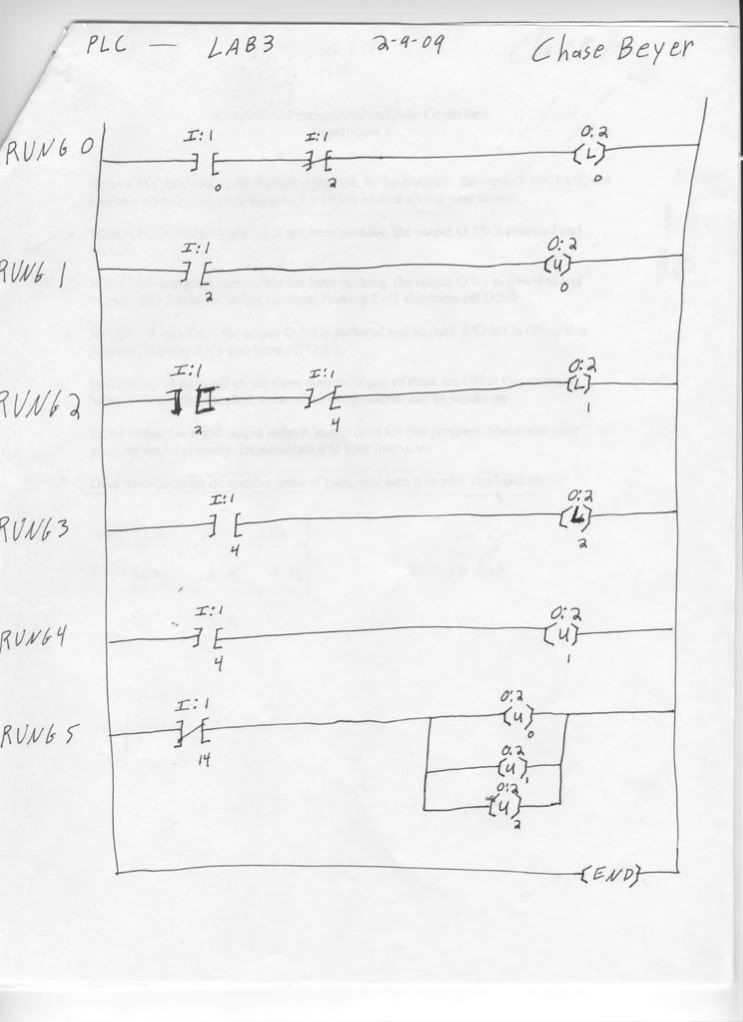

Write a PLC program to do the following task. In the program , the inputs I:1/0, I:1/2, and I:1/4 are normal open push buttons, I:1/14 is a normal closed push button.

When I:1/0 is pushed and I:1/2 is not being pushed, the output O:2/0 is powered and latched.

When I:1/2 is pushed and I/4 is not being pushed, the output O:2/1 is powered on and latched. If O:2/0 is ON at the moment, pushing I:1/2 also turns off O:2/0.

When I:1/4 is pushed, the output O:2/2 is powered on and latched. If O:2/1 is ON at the moment, pushing I:1/4 also turn off O:2/1.

Pushing I:1/14 turns off all three outputs, if any of them are ON at this moment. When I:1/14 is being pushed, none of the three outputs can be turned on.

Use the latch and unlatch command for this program.

------------------------------------------------------------

I attached the program I have written in the attachment. It is a .RSS file.

Ignore the last RUNG, thats where I need help.

Any help you can offer me would be very much appreciated!

Here is the Assignment

------------------------------

Write a PLC program to do the following task. In the program , the inputs I:1/0, I:1/2, and I:1/4 are normal open push buttons, I:1/14 is a normal closed push button.

When I:1/0 is pushed and I:1/2 is not being pushed, the output O:2/0 is powered and latched.

When I:1/2 is pushed and I/4 is not being pushed, the output O:2/1 is powered on and latched. If O:2/0 is ON at the moment, pushing I:1/2 also turns off O:2/0.

When I:1/4 is pushed, the output O:2/2 is powered on and latched. If O:2/1 is ON at the moment, pushing I:1/4 also turn off O:2/1.

Pushing I:1/14 turns off all three outputs, if any of them are ON at this moment. When I:1/14 is being pushed, none of the three outputs can be turned on.

Use the latch and unlatch command for this program.

------------------------------------------------------------

I attached the program I have written in the attachment. It is a .RSS file.

Ignore the last RUNG, thats where I need help.

Any help you can offer me would be very much appreciated!