James Mcquade

Member

Hi everyone,

Our company has had a problem with a vendors machine, it keeps failing parts. As we all know, no one makes bad parts so its got to be the vendors machine.

I was asked to look into the electrical part of the test machine and did discover several problems and fixed them.

By doing all this, the machine now operates much better. Now the quality department has made this machine a six sigma project and wants me to write up everything. that parts ok.

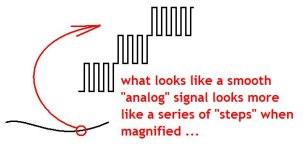

How do i tell the quality bunch what the error associated with

the analog input card is?

I have an AB 1746-NIO4I card. (2) 4-20 ma inputs and (2) ma outputs. Looking at the specs is greek to me when i have to take all the associated errors into consideration.

Any help would be much appreciated.

thanks in advance,

james

Our company has had a problem with a vendors machine, it keeps failing parts. As we all know, no one makes bad parts so its got to be the vendors machine.

I was asked to look into the electrical part of the test machine and did discover several problems and fixed them.

By doing all this, the machine now operates much better. Now the quality department has made this machine a six sigma project and wants me to write up everything. that parts ok.

How do i tell the quality bunch what the error associated with

the analog input card is?

I have an AB 1746-NIO4I card. (2) 4-20 ma inputs and (2) ma outputs. Looking at the specs is greek to me when i have to take all the associated errors into consideration.

Any help would be much appreciated.

thanks in advance,

james