hai guys.. ..

..

i m having some issue with electrical motor again which using auto trans stater ..which this time it not my own panel insted it was given from other plant and send to us to fix it ..and the diagram was made by my senior manager..

problme now..when start the motor without load it seem working good but than when we increass load into it ..it just start to triping at 200amp more or less..

i do find something really wrong with the diagram and wiring made ..but than the other team claim it was working good for them until they ship out to us..

normally when i made my own auto trans stater..

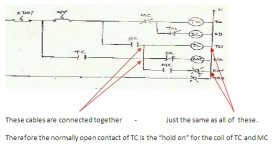

auto trans contactor would not remain on when delta contactor are in ..but this diagram show the otherway round and i m confuse seem my senior manager cant understand what language me talking too him..(i guess)

can you guys have look and correct what wrong it ..

as far i see the TC are remain on even when MC are cut in which tc supply still the and output 65% tapping from auto trans.

i m having some issue with electrical motor again which using auto trans stater ..which this time it not my own panel insted it was given from other plant and send to us to fix it ..and the diagram was made by my senior manager..

problme now..when start the motor without load it seem working good but than when we increass load into it ..it just start to triping at 200amp more or less..

i do find something really wrong with the diagram and wiring made ..but than the other team claim it was working good for them until they ship out to us..

normally when i made my own auto trans stater..

auto trans contactor would not remain on when delta contactor are in ..but this diagram show the otherway round and i m confuse seem my senior manager cant understand what language me talking too him..(i guess)

can you guys have look and correct what wrong it ..

as far i see the TC are remain on even when MC are cut in which tc supply still the and output 65% tapping from auto trans.