Hello all,

I am on the phone to someone who is remotely trying to diagnose a motor problem

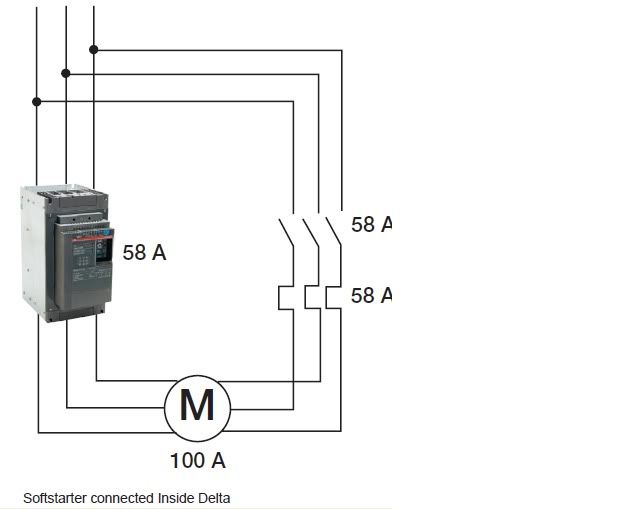

it is a 30kW 4 pole, 400VAC ABB motor connected to a ABB softstarter. It is wiring in an 'inside delta' configuration. 6 wire connection to the motor. It has been working for a time months before it failed to run, the wiring has not been touched and there is another one next to it the same that is working without problem.

Now it is not running, completely silent, the motor is windings have been checked that are all 4 ohms (U1 to U2, v1 to v2 & W1 to W2) They have confirmed 230VAC between phases.

They have also swapped over the softstarters and still doesn't run. They are suggesting it is the motor but if there is resistance and voltage across it - surely there should be some motor movement or if not current increase??

Any ideas??

I am on the phone to someone who is remotely trying to diagnose a motor problem

it is a 30kW 4 pole, 400VAC ABB motor connected to a ABB softstarter. It is wiring in an 'inside delta' configuration. 6 wire connection to the motor. It has been working for a time months before it failed to run, the wiring has not been touched and there is another one next to it the same that is working without problem.

Now it is not running, completely silent, the motor is windings have been checked that are all 4 ohms (U1 to U2, v1 to v2 & W1 to W2) They have confirmed 230VAC between phases.

They have also swapped over the softstarters and still doesn't run. They are suggesting it is the motor but if there is resistance and voltage across it - surely there should be some motor movement or if not current increase??

Any ideas??