Lakee911

Member

Hi All,

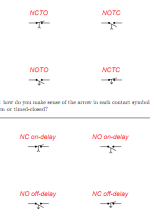

I know this is a *PLC* forum, but I'm trying to create a hardwired circuit using one timer that will shutdown a motor when it fails to get a close-open-close cycle of a limit switch every two minutes. In addition, I'd like for it to illuminate a lamp that shows we have zero speed. There is no chance of the device stopping with the limit open.

Can someone look at logic attached and see if I've designed this correctly?

Thx,

Jason

I know this is a *PLC* forum, but I'm trying to create a hardwired circuit using one timer that will shutdown a motor when it fails to get a close-open-close cycle of a limit switch every two minutes. In addition, I'd like for it to illuminate a lamp that shows we have zero speed. There is no chance of the device stopping with the limit open.

Can someone look at logic attached and see if I've designed this correctly?

Thx,

Jason