The company I work for asked me to program a simple PLC (Apparently since I'm a computer programmer, it should be easy for me). Anyways, I usually learn pretty fast but I'd love some help to get started. The program goes like this :

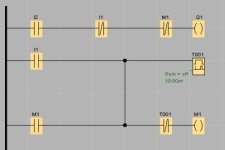

There's an input that comes from the cylinder exit. When that cylinder exit is clear, it triggers the output. When it's not, the output stays closed.

There's another input that comes from the conveyer traffic with a timer. If the cylinder exit is clear, it triggers the output, if not, it waits 10 secs and tries again.

I *hope* that was clear enough. I'll be programming this on a Logo!, but if I can have a base idea of what the ladder looks like I can switch it to the Logo!.

Thank you so much for all your help !!!

There's an input that comes from the cylinder exit. When that cylinder exit is clear, it triggers the output. When it's not, the output stays closed.

There's another input that comes from the conveyer traffic with a timer. If the cylinder exit is clear, it triggers the output, if not, it waits 10 secs and tries again.

I *hope* that was clear enough. I'll be programming this on a Logo!, but if I can have a base idea of what the ladder looks like I can switch it to the Logo!.

Thank you so much for all your help !!!