I'm a complete noob to this...

Basically I have to design a project that can be done in a 2 hour lab session, and I wanted to use it as a chance to introduce PLCs.

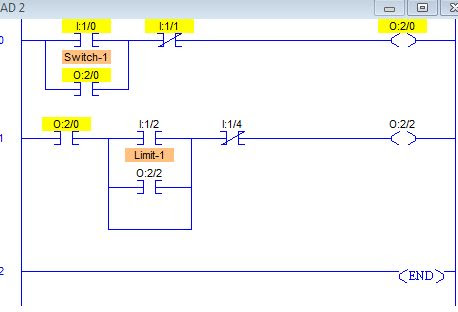

My idea is to implement and program a PLC that can run a motor forward, hit a limit switch, reverse, hit a limit switch and do this continuously, or until it is stopped by the user.

How can this be done, how do the limit switches fit into the basic motor seal-in circuit? What type/model of PLC would be cheap and easy to implement in a classroom setting? I basically need to figure out how to design this in detail, but I don't actually need to build it myself.

Basically I have to design a project that can be done in a 2 hour lab session, and I wanted to use it as a chance to introduce PLCs.

My idea is to implement and program a PLC that can run a motor forward, hit a limit switch, reverse, hit a limit switch and do this continuously, or until it is stopped by the user.

How can this be done, how do the limit switches fit into the basic motor seal-in circuit? What type/model of PLC would be cheap and easy to implement in a classroom setting? I basically need to figure out how to design this in detail, but I don't actually need to build it myself.