NewEngineer

Member

Hi Guys,

I'm new to controls and PLCs and this might have a trivial answer.

I have a small project with a PLC and a inverter. The inverter accepts power (kW) setpoints from our PLC. All through Modbus TCP.

The requirement is when there is a setpoint change from the PLC the inverter must ramp up to the setpoint value ie. not do a step response. The ramp rate is defined as kW per minute.

For example the inverter is switched on and is required to ramp up to 100kW.

Inputs:

Initial Power Output: 0kW

Setpoint: 100kW

Ramp-rate: 20kW/min

This means the inverter must ramp linearly from 0kW to 100kW in 5mins.

From my understanding (please correct me if I've wrong) is the PLC outputs signals every scan cycle (outputs are updated every scan). This means the PLC would be sending a new setpoint at a repeated time interval (fastest would be the fixed scan time) in order to ramp up to the setpoint.

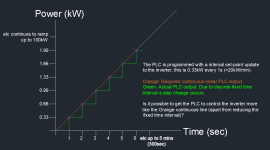

The initial thinking was sending time interval setpoint points to the inverter. eg., add 0.33kW (20kW/60) to the current power output at every 1s trigger (This is an example, time interval can be reduced but problem still exists with smaller steps). The attached PNG graph explains the problem more clearly.

Is it possible to produce a linear signal on the inverter for this application without the steps, if so how?

Thanks in advance!

I'm new to controls and PLCs and this might have a trivial answer.

I have a small project with a PLC and a inverter. The inverter accepts power (kW) setpoints from our PLC. All through Modbus TCP.

The requirement is when there is a setpoint change from the PLC the inverter must ramp up to the setpoint value ie. not do a step response. The ramp rate is defined as kW per minute.

For example the inverter is switched on and is required to ramp up to 100kW.

Inputs:

Initial Power Output: 0kW

Setpoint: 100kW

Ramp-rate: 20kW/min

This means the inverter must ramp linearly from 0kW to 100kW in 5mins.

From my understanding (please correct me if I've wrong) is the PLC outputs signals every scan cycle (outputs are updated every scan). This means the PLC would be sending a new setpoint at a repeated time interval (fastest would be the fixed scan time) in order to ramp up to the setpoint.

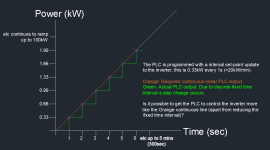

The initial thinking was sending time interval setpoint points to the inverter. eg., add 0.33kW (20kW/60) to the current power output at every 1s trigger (This is an example, time interval can be reduced but problem still exists with smaller steps). The attached PNG graph explains the problem more clearly.

Is it possible to produce a linear signal on the inverter for this application without the steps, if so how?

Thanks in advance!

Last edited: