Thanks for the screenshot and explanation. Most Logix PLCs are certainly able to handle two messages from three peer devices on average every 1.2 seconds, so it's *unlikely* that you're running out of buffers or bandwidth. Obviously I can't tell how heavily loaded your controllers are on memory and utilization.

If I were troubleshooting this system, I would probably take two initial approaches.

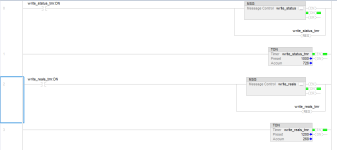

The first is to figure out what kind of failure is happening from the perspective of the PLC2, PLC3 and PLC4 controllers that are initiating the messages. That means capturing the .ER bit, and the .ERR and .EXERR codes in logic. Sometimes I put them into an array with a timestamp, sometimes I send them to an alarming subsystem (like with ALMD and PanelView 5000), sometimes I just use a counter and come back to look at it frequently.

And I would try to use the receiving controller a role in the diagnostics too. I would add another element to the data block you're sending to PLC1 and make that a Watchdog value that increments by one every time the MSG is sent, or even one that contains a timestamp. Then logic in the receiving controller can monitor that value to see exactly how long the data goes without being updated, and precisely when it occurs.

My colleague OkiePC mentioned a couple of other things you could do with this logic, including setting the Unconnected Message Timeout value to something less than its 30 second default, or checking the box to be sure you're using a Connected message. You can also add a manual timeout timer; if the .EN bit is true (but the /DN and /ER bits are both false) for X milliseconds, the timer manually sets the .TO bit for the MSG control block, which has the same effect as the MSG naturally timing out because it didn't get an acknowledgement from the other controller.

You might have a noisy network. You might have a bad network cable. You might have a switch that's connected to a power supply that browns out every time the main compressor comes on at the same time as more than one microwave in the lunchroom but that comes right back up as soon as the burrito is warm and the accumulator tank is back up above 90 PSI.