sparkytex

Lifetime Supporting Member

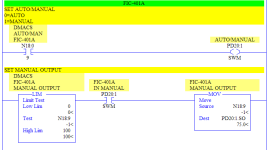

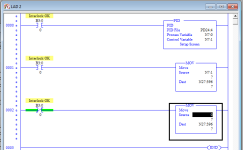

Hello everyone. I was asked to make an adjustment to one of our existing PLC programs this morning. I'm using a AB PLC5 with RSLogix 5. There's a PID controller for Level in our acid plant "atmopsheric tank". Theres a 4-20 mA valve (control variable) in line with our Acid plant "Pressure tank" which is where the acid is being pumped. Theres a level indication (process variable) on the Atmos. tank itself. In line with the valve is an acid pump and motor. What they requested was an interlock be added so that when the acid pump shuts off, the valve in line with the tank gets closed. there asking this because the check valve on the line isnt working and backpressure was building up and shutting the motor off under O/L in certain conditions. The valve is fail to close, and the scale in the PID is min0=0 and max0=100 (0-100). How should I go about writing a zero or 4 mA to the valve when the pump shuts off. Output module is a 1771 NOC High resolution I/O module. Analog output address is N27:396, and PID file is PD23:4. Also there is an running feedback from the pump to the PLC I:010/15 which I could utilize. Not super familiar with PID's and how they work, but I do need to learn how to program them on rslogix5 and rslogix 5000 asap!!

thanks,

thanks,