iconoclast

Member

There all I am currently having some trouble with a program and I would appreciate some ideas and help.

The main program is based on tank filling process and I have inserted the heating and mixing of the fluid in a sub routine once the tank is filled.

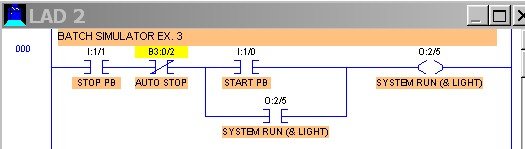

Would you suggest a way I could stop the process upon the pressing of the stop button anywhere during the process and when the start is pressed the problem will continue where it left off?

Somewhat of a pause button situation if you will

Thanks

Iconoclast

The main program is based on tank filling process and I have inserted the heating and mixing of the fluid in a sub routine once the tank is filled.

Would you suggest a way I could stop the process upon the pressing of the stop button anywhere during the process and when the start is pressed the problem will continue where it left off?

Somewhat of a pause button situation if you will

Thanks

Iconoclast