I'm working on a PID ladder logic program to control a small process trainer as a college project. 2 valves in a split range setup control hot and cold water going to a heat exchanger which heats or cools water circulating in a tank. A RTD in the tank measures the temperature as the variable.

Basically. I'm having some trouble with logic though as I don't have a lot of experience with it.

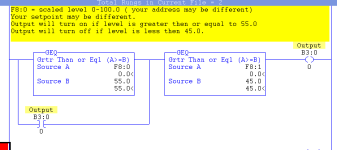

Here's what I have so far. I'm using a Allen Bradley 1500. With an RTD card and analog I/O cards. The RTD is I:3.0. According to the RTD the ouput range is -32767 to 32767 and I have that scaled to -200 to 800 degrees celcius which is its temp range even though I'll only be using a small part of that range. That's outputted to the pid function as the variable, then the output of the pid controller is changed from a 0 to 100 scale to 0 to 16383 for a 4-20 ma signal to the current-to-air transducer that tees to the valves, which is the O:2.0 you see.

Does this make sense to anybody? What else do I need for this to work? I still need to make another loop to control the level in the tank but I'd like to get one thing working at a time.

Basically. I'm having some trouble with logic though as I don't have a lot of experience with it.

Here's what I have so far. I'm using a Allen Bradley 1500. With an RTD card and analog I/O cards. The RTD is I:3.0. According to the RTD the ouput range is -32767 to 32767 and I have that scaled to -200 to 800 degrees celcius which is its temp range even though I'll only be using a small part of that range. That's outputted to the pid function as the variable, then the output of the pid controller is changed from a 0 to 100 scale to 0 to 16383 for a 4-20 ma signal to the current-to-air transducer that tees to the valves, which is the O:2.0 you see.

Does this make sense to anybody? What else do I need for this to work? I still need to make another loop to control the level in the tank but I'd like to get one thing working at a time.