steelblue48310

Member

I'm about to undertake a project on a L18ERM controller, which will be attached to a PV1000 HMI, and I think I might need to make extensive use of Arrays to get it to work. Since I am not yet clear on how to use an Array at all, I thought I would do some reading first... I found several posts regarding Arrays and Recipes, but I didn't find quite enough to dig right in and start. So, is there a good place to start my quest for knowledge? (yes... Google is my friend... but, most of my searches landed me here anyway)

Here's a basic description:

This is a 'single axis' motion (servo motor) that is attached to a set of rollers that moves material into a stamping press. (Feed to length application)

I was able to get a simple version of this to work, and by simple I mean that I have only a single repeating length based on a physical input. (Indexing)

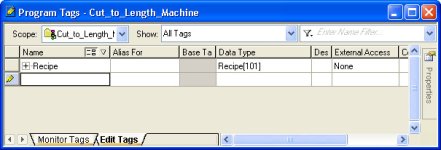

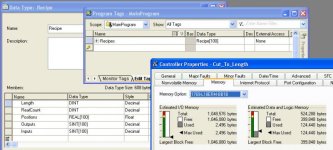

Now I've been asked to take this to the 'next level', which will require multiple lengths and potential reverse movements, all based upon a 'job recipe'. I will need to be able to store as many as 100 'recipes' to be stored and called up as needed.

Each 'job' may have just a few repeating moves, while others may have complex forward and backwards moves, and also trigger outputs along the way... All this needs to be done via the HMI.

Thanks... ~Mike

Here's a basic description:

This is a 'single axis' motion (servo motor) that is attached to a set of rollers that moves material into a stamping press. (Feed to length application)

I was able to get a simple version of this to work, and by simple I mean that I have only a single repeating length based on a physical input. (Indexing)

Now I've been asked to take this to the 'next level', which will require multiple lengths and potential reverse movements, all based upon a 'job recipe'. I will need to be able to store as many as 100 'recipes' to be stored and called up as needed.

Each 'job' may have just a few repeating moves, while others may have complex forward and backwards moves, and also trigger outputs along the way... All this needs to be done via the HMI.

Thanks... ~Mike