In my career I have worked for and with dozens of different companies, an every single one had a different drawing number system. And every single one was convinced theirs was the best and most logical system.

I have reached a few conclusions:

- Keep it simple. The systems that try to convey a lot of part configuration or function information in the drawing number are more work than they are worth.

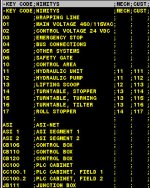

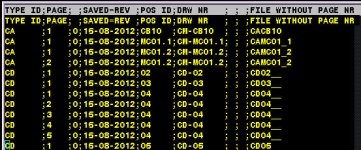

- In general, non-specific part numbers seem to be most efficient. The savants that can remember lots of part numbers can remember lots of any numbers! If you want to use a prefix or suffix for broad categories, such as 20 for PLC stuff and 10 for hydraulic stuff that can be useful (But it can also lead to endless time sucking brain numbing arguments between guys that should be doing something useful instead.) You can get carried away easily - a separate part number sequence for analog inputs and analog outputs, for example, adds little to information retrieval and less to company profitability.

- Document it. Every engineer, purchasing agent, draftsman, and field service tech should have a sheet explaining the system. If it wont fit on an 8-1/2 x 11 (or less) in 12 point font it is too complicated.

- Be Consistent. Establish a system and rigidly enforce it. Anyone with a bright idea for improvement needs to be slapped down, even if it is a better idea. The company should have better things to do than renumber drawings every three years.

- Remember the point. Drawing numbers are simply a means to aid information retrieval. They are not intended to provide an intellectually satisfying hobby for the engineering department rain men.