Hello this is jitu. I am a new in this PLC Ladder coding. Anyone help me to write this problem. I am also try to solve this but not successfully complete.

3 conditions are:

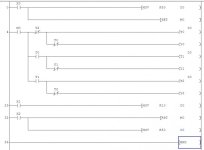

1. When you press the button switch X0 ,then the lamp yo is ON for 5 second. When the lamp yo turns off after 5 second then the lamp y1 is ON for 5 second. When the lamp y1 turns off after 5 second then the lamp y2 is ON for 5 second. This proces Successively repeated in this manner.

2. when you press the button x1, then the duration of 5 second timer is switched to the 1-second timer during this process.

3. When you press the button switch X2( stop button) , then the process is stop and the duration of 1 second timer is returned to the 5 second timer (default setting)

Therefore, I want to create a PLC Program that fulfill all the all above conditions.

3 conditions are:

1. When you press the button switch X0 ,then the lamp yo is ON for 5 second. When the lamp yo turns off after 5 second then the lamp y1 is ON for 5 second. When the lamp y1 turns off after 5 second then the lamp y2 is ON for 5 second. This proces Successively repeated in this manner.

2. when you press the button x1, then the duration of 5 second timer is switched to the 1-second timer during this process.

3. When you press the button switch X2( stop button) , then the process is stop and the duration of 1 second timer is returned to the 5 second timer (default setting)

Therefore, I want to create a PLC Program that fulfill all the all above conditions.