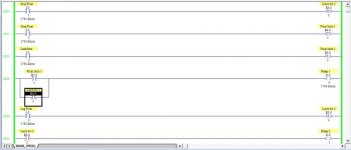

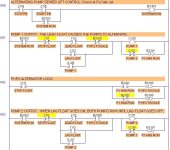

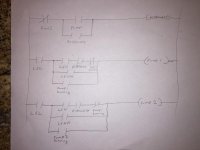

I've programmed this AB Micro Logix 1000 to mimic an alternating pump sewer lift control electronic board.

This does everything I want including latched floats until the tank is drained to the stop float.

There is a lead float which I want to alternate. There is a lag float, which controls both pumps, in case the lead pump fails. I will add an alarm and siren for high level.

I'm stuck on making an alternating circuit controlled from one input. I looked at the examples posted here, and tried to use them including the counter, and one other, but no success. I need it to latch so the pump doesn't cycle.

This does everything I want including latched floats until the tank is drained to the stop float.

There is a lead float which I want to alternate. There is a lag float, which controls both pumps, in case the lead pump fails. I will add an alarm and siren for high level.

I'm stuck on making an alternating circuit controlled from one input. I looked at the examples posted here, and tried to use them including the counter, and one other, but no success. I need it to latch so the pump doesn't cycle.

Last edited: