drbitboy

Lifetime Supporting Member

I have 2 pumps not alternating at a lift station. When im at the panel and use the test switches to initiate the pumps,it alternates in the PLC. But after I leave it just keeps running the [one] same pump until I come back and go into test mode again. would something like that be purely mechanical? or could the plc be corrupted also?

it is a lead/lag set-up, it does switch the lead when ever i toggle the float test switch that is in parallel with the float that turns on the pump.

It was in fact a faulty float switch, the one that the maintenance man said he checked and verified was working. thanks for the help.

The lag float switch was starting the lag pump and so it didnt switch the leads

The behavior described above suggests that OP's lead-lag logic could be improved.

The evidence for this is that the lag float switch was starting the lag pump only; in what I assume is the canonical implementation of lead-lag, the lag float switch should cause both pumps to start, regardless of lead-lag state.

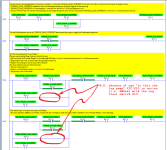

Cf. this thirteen year old thread and my attached reinvention of this particular wheel.

The comments in the PDF explain the logic, but the guts of the algorithm, and the issue I am raising, are shown below. Rungs 0002:0003 implement the lead-lag toggle logic; Rungs 0004:0005 turn the pumps on and off in response to float switch changes. I suspect that, in OP's program, the lag float switch XICs are ANDed with an XIO/XIC of the lead-lag status. The lag float switch will normally not be triggered unless the inlet flow exceeds what one of the two pumps can handle, so there is no significant downside to ensuring both pumps run after the lag float switch triggers. Note that also, for the issue that spawned the initial post, i.e. the lead float switch failing to trigger as it should, that issue still could have been noticed because, instead of the lead-lag logic failing, both pumps would be, apparently unnecessarily, running.

Also note that my implementation triggers the lead-lag toggle at the end of a lift, instead of the beginning. That would fix the original problem, even though the problem itself was due to a mis-implementation of lead-lag in the first place.