I'm new to Allen-Bradley PLCs & RSLogix 500 - cue stupid question - and I want to set a timer preset value from an HMI. I was surprised to see I could only put a constant numeric value into the Preset field of the TON instruction

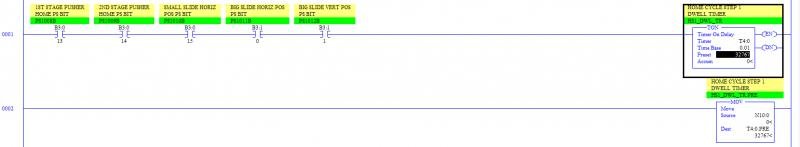

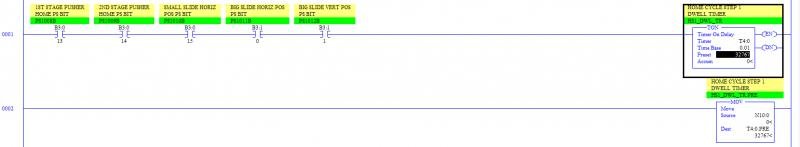

I've googled and I'm MOVing the value to the .PRE value of the timer. I've set the Preset field to 32767 and perform the MOVe on the next rung. I'm guessing that it will work okay but it seems very inelegant. Won't the preset value be written to 32767 briefly on each scan before being written back to the required value?

Is there a better way to do it?

I've googled and I'm MOVing the value to the .PRE value of the timer. I've set the Preset field to 32767 and perform the MOVe on the next rung. I'm guessing that it will work okay but it seems very inelegant. Won't the preset value be written to 32767 briefly on each scan before being written back to the required value?

Is there a better way to do it?