If it were my system, I would increase the size of the block transfer so I had more data to work with.

There are five basic things you need to modify to do this:

1. In PanelBuilder32, change the size of the Block Transfer that the PV600 expects.

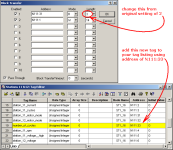

In the project tree, select Communications Setup -> Comms Setup button -> Block Transfers button. Change the first Block Transfer (the Read) from 2 words to 10 words.

2. In PanelBuilder32, create a Tag with the data you want to use. In the project tree, select Tag Editor, then hit Insert.

Give it a name like "Cycle_Qty", select Unsigned Integer as the datatype, and address it to N111:30.

3. In PanelBuilder32, create the Numeric Entry object for your "Number of Cycles" entry. I would use a Numeric Entry Keypad Enable object, and address the Write tag to N111:30.

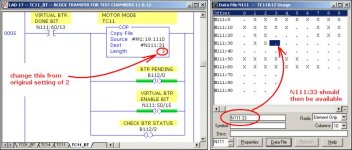

4. In RSLogix 500, change the configuration for the Block Transfer Read.

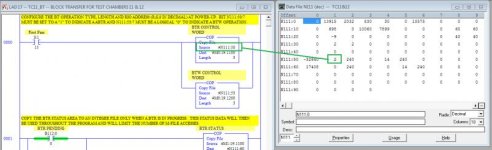

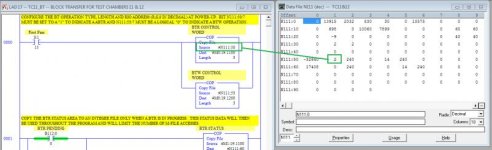

In Ladder File TC11_BT, the first rung configures the Block Transfer for this PanelView terminal using the data stored in N111:50, 51, 52.

The value in N111:51 is the Length of the block transfer. Change this from 2 to 10.

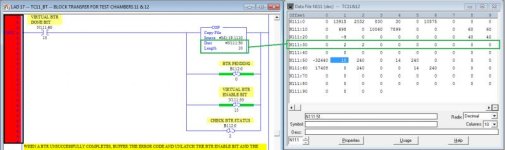

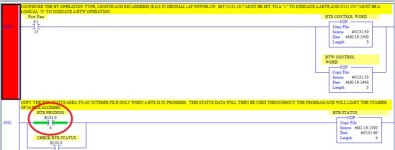

5. In RSLogix 500, change the amount of data copied out of the BTR result buffer.

In Ladder File TC11_BT, Rung 5 grabs the data from the BTR result buffer and puts it into N111:31-32. Edit that rung so that the Destination address is N111:30 and the Length is 10 instead of 2.

Download those changes, of course, to the PanelView and the SLC-500. You can do those SLC-500 edits online if you wish.