electric101

Member

The good news is I became a dad today, i'm posting from the hospital at this moment.

the bad news is i've still not figured out reading my analog data on this devicenet FLEX IO system.... all my other posts go unanswered, but i think that might be because of the complexity of which i composed the question.

i've made some progress so maybe its simplified now

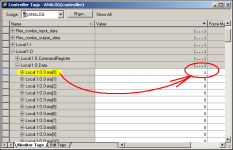

I just need to know that what i've got going here is in the right direction.

and if that answer is yes i need to know how to determine the data that goes in the communication tab basically to path out the read to the module. Channel? , rack?, group?, slot?

here is my .dnt file and my .vcd file which should tell you all the actual hardware being used.

thanks guys.

the bad news is i've still not figured out reading my analog data on this devicenet FLEX IO system.... all my other posts go unanswered, but i think that might be because of the complexity of which i composed the question.

i've made some progress so maybe its simplified now

I just need to know that what i've got going here is in the right direction.

and if that answer is yes i need to know how to determine the data that goes in the communication tab basically to path out the read to the module. Channel? , rack?, group?, slot?

here is my .dnt file and my .vcd file which should tell you all the actual hardware being used.

thanks guys.