drbitboy

Lifetime Supporting Member

my laptop does not have zip file abilities.

How old is the laptop? What OS is it running? Is it not running Windows?

Windows has had built-in zip capability for some time, going back to XP at least; IIRC.

my laptop does not have zip file abilities.

Yep, corrrect so far.drbitboy,

so far i understand the following.

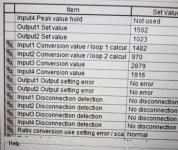

Unit # and voltage / current dip switches.

DM addresses - this sets up how the module is used.

CIO addresses is where the data in the analog is located.

No.i do not understand how to configure the conversion data holding addresses

for example C2015 to C2018 is stored in D00100 to D00103 (from the manual).

There is a similar formula, but they are also shown in the module setup under the IOTable.How do you get the D numbers?

the CIO numbers range from 2000 + (n*10) to 2000+(n*10)+9

where n is the unit number.

HOW do you compute the corresponding D numbers??

This is based on 2000 + (n x 10).where i am having trouble is how you determine the storage numbers for C2010 to C2019.

The manual shows an example of copying the CIO area to DM area for program use. You do not have to do this.for example C2015 to C2018 is stored in D00100 to D00103 (from the manual).

this is unit 1.

Correct.what if this was unit 3? the CIO numbers would be C2030 to C2039.

You do not need to.where would you move these data registers in order to use them ?

For D100-103 etc as per the manual, these are whatever you select (that are not already used or pre-allocatedhow do you determine the register numbers?

Not really, it is just a legacy practice to set the card up as opposed to using the IO Table. It is like a brute force method so will always return to that when PLC starts..in my program i have the following

Power_ON mov &243 D20100 ( enable the i/o card)

Mov &42505 D20101 (tell the card how it will be used)

Mov &194 D20135 (can't remember)

Do i need these statements in the program since i used the software to tell the card how it is used? i do not see this in the card

On this, CX-P allows for you to view in Hex, signed & un-signed.the word is set to signed decimal channel.

This is very easy. Do you want real world units?my next issue will be how to scale the data and offset values.