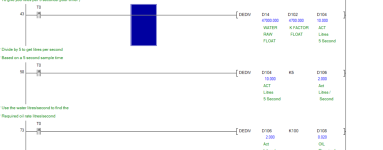

This is the way I would do it. See Very rough diagram.

Set flow counters to zero, open both water & oil valves dose in fluids until set points reached.

In the mean time when a small level in tank, divert valve back to tank & run blender. Continue blending back into tank until mix is well blended, when batch required, open divert to sump & discharge.

What I get from your schematic is that if you're going for a 1% solution in 100 Litres, you would add 1 Litre lube with 99 Litre water through regular Solenoid Valves with a Flow sensor/meter and let both these liquids enter a tank. The tank has an solenoid valve for discharge.

You have a Static Mixer and a 3-way valve downstream of the tank, with one line going towards output to the sump, and one to return the liquid back to the tank.

A pump recirculates liquid from the tank through the Mixer and back into the tank for a set amount of time. This mixed liquid is then fed to the sump through the other port on the 3-way valve.

Questions :-

1. If I need to charge an entire CNC sump, the size of this pre-mix tank would be too large and thus the size of my Dispensing Unit.

2. Why is there a need to make multiple passes through the blender for the two liquids to mix?

3. How does this offer an advantage over an Inline mixing?