Ron Beaufort said:

....people who believe (incorrectly) that:

(a) an XIC instruction "Examines a SWITCH" to see if it's ON ...

(b) "green on the screen means TRUE" ...

(c) "power-flow through the rung will cause an OTE to energize an output" ...

and other such misconceptions

Ron didn't offer an explanation as to why these statements may be incorrect, and I feel that without such explanation, his comments may cause confusion in the minds of the less experienced....

I offer the following, hopefully it covers all the bases.....

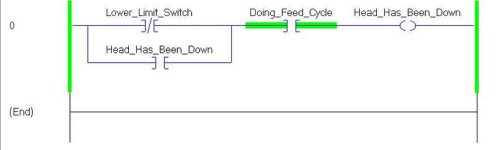

(a) an XIC instruction "Examines a SWITCH" to see if it's ON ...

The only thing I can see wrong with this statement is the use of the word SWITCH. A switch can be wired NO, or NC, so the concept of ON or OFF is ambiguous - the switch may be ON or OFF (as indicated by its legend or position), but its contacts may be closed, or open, in that ON position.

Boolean (bit) instructions in PLCs examine the state of the memory bit used to store data. That memory bit may be data from input modules/cards, or it can be an "internal" memory bit, set or reset by other logic.

However, if we take the word SWITCH to mean any memory bit that can be "switched" on or off, then statement (a) is perfectly OK.

(b) "green on the screen means TRUE" ...

Mostly this is a correct assumption. When this isn't the case, then there is invariably a timing issue involved.

The programming software highlights (green) an XIC instruction when it sees the attached bit location is ON, logic 1, or true.

It may not be continuously true (in the PLC), but at the time that the data was read from the PLC, it was.

The visual interpretation by the software is that it will display what it sees at the time it sees it.

(c) "power-flow through the rung will cause an OTE to energize an output" ...

Two things here -

1. An OTE will both

Energize, and

De-Energize "an output" (see below).

I dislike the use of Energize/De-Energize in this context.

"power flow through the rung" is known as "rung logic continuity".

When the rung evaluates as TRUE, an OTE will write a "1" to the addressed bit location, but it will also write a "0" when rung logic continuity is false.

2. "an output" is simply a copy of an internal memory location to an output module.

There are cases where the internal representation of an output value (digital or analog), do not represent what is actually happening at the physical output. Forcing may be in use, or there may be multiple "writes" to the same location.

I tried to keep this as short as possible - and I bet I've missed a few things - the most important thing to grasp is that a PLC is just a machine, a computer program that interprets and acts on the data that is presented to it