Hello,

I have following control task. I have to limit a current drawn from a source of power in a grid where I have following power consumptions:

The current drawn from the source of power can be limited via these action variables:

I have been thinking about the control structure suitable for this control task. It seems to me that the so called split range control could be a solution (at least as far as the first two action variables). The problem which I have regards the last two action variables. I am not sure how to integrate them

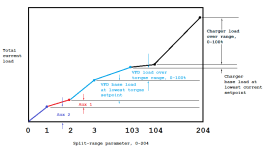

organically into the split range control structure. The idea which I have is depicted on the attached figure.

i.e. the logic signals are simply activated based on the value of the output of the PI controller in the same manner as the charging current setpoint and torque setpoint. I am not sure whether this approach can work in practice. Does anybody know a better approach for integration of action variables of logic type into split range control structure? Thanks in advance for any suggestions.

I have following control task. I have to limit a current drawn from a source of power in a grid where I have following power consumptions:

- battery charger

- variable frequency drive

- aux power consumption 1

- aux power consumption 2

The current drawn from the source of power can be limited via these action variables:

- lowering the charging current setpoit for the battery charger

- lowering the torque setpoint for the variable frequency drive

- activating the logic input of the aux power consumption 1 for turning the consumption off

- activating the logic input of the aux power consumption 2 for turning the consumption off

I have been thinking about the control structure suitable for this control task. It seems to me that the so called split range control could be a solution (at least as far as the first two action variables). The problem which I have regards the last two action variables. I am not sure how to integrate them

organically into the split range control structure. The idea which I have is depicted on the attached figure.

i.e. the logic signals are simply activated based on the value of the output of the PI controller in the same manner as the charging current setpoint and torque setpoint. I am not sure whether this approach can work in practice. Does anybody know a better approach for integration of action variables of logic type into split range control structure? Thanks in advance for any suggestions.