I think Panic Mode has it pretty close.

However, I have a few suggestions...

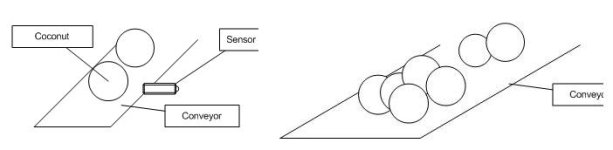

First, I would definitely use a sender/receiver setup. They should be mounted at an angle so that coconut hairs won't tend to cover the device on the lower side. You might also include a small air jet to keep the lower lense clear of hair dust.

I agree that there would be a tendancy to jam, especially considering the friction associated with the coconut hair, further aggrevated by the driving force of the belt. I can see where two coconuts could be lodged into each other and not be inclined to become unlodged... even with free rolling rollers, as Panic described.

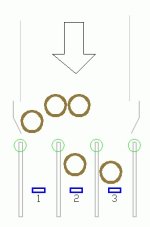

I would suggest that the rollers all be driven in the same direction. Consider the rollers from left to right as #1, #2, #3 and #4. All rollers are driven clockwise.

The left chute uses rollers #1 and #2.

The middle chute uses rollers #2 and #3.

The right chute uses rollers #3 and #4.

On the left chute:

Roller #1 tends to drive a coconut into the left chute.

Roller #2 tends to drive a coconut out of the chute.

On the middle chute:

Roller #2 tends to drive a coconut into the middle chute.

Roller #3 tends to drive a coconut out of the chute.

On the right chute:

Roller #3 tends to drive a coconut into the right chute.

Roller #4 tends to drive a coconut out of the chute.

I think that even if the staging area, the area just before the chutes, is filled with coconuts that the setup I described would work as far as passing coconuts into the various chutes without jamming.

I'm still concerned about the idea of separation between coconuts so that an accurate count can be made. I'm assuming that there is a minimum size of coconut... small ones should be sorted out at some point before this part of the process.

Consider this (this is a very rough idea that needs more work)...

Looking at Panic Mode's drawing as displayed on the screen, at a point just after the entry to the chute (the distance should be at least as large as two coconuts end-to-end) and well before the photo-eyes, visualize a paddle arragement that looks like an inverted "T". Looking from above, the depth of the paddle should be about as deep as the diameter of an average coconut. The paddle is to be mounted in the center of the chute on a pivot that goes down through the common point of the horizontal and vertical parts of the "T".

In general, the vertical part of the inverted "T" leans to the left or the right. If the "T" is leaning left, then as a coconut comes to the "T" the coconut hits the right side of the cross bar (the horizontal part of the "T") and passes through on the right side of the "T". Meanwhile, the "T" is driven to lean to the right as the coconut passes through. The following coconut acts similarly but this time the coconut passes on the left and drives the "T" to lean to the left. (Concern: There might be a race-condition between the right and left side.)

This should impose a reasonably reliable gap between the coconuts thus making it easier to count them.

Now... it seems that the geometry of the chute needs to be configured somewhat to accommodate the geometry of the "T" toggle. The chutes probably need to fan-out a bit... but not so much that the photo-eye would miss a count... hmmm...

A thought just occurred to me... if the "T" paddles can operate reliably then maybe you don't need the eyes at all! Maybe the "T" toggle actions can be counted...?