NFPA 79 13.2.4.3.

Where color-coding is used for identification of conductors, the following color codes shall be permitted to be used.

(1) BLACK for undrounded AC and DC power conductors.

(2) RED for ungrounded AC control conductors

(3) BLUE for ungrounded DC control conductors.

13.2.3.2

Where an AC circuit includes a grounded conductor [this mean a NEUTRAL] this conductor shall be WHITE, GRAY, or three continuous WHITE stripes on other than GREEN, BLUE, or ORANGE insulation along its entire length.

13.2.3.2 (1) designates that white with a blue stripe shall be used for a grounded current carrying DC circuit conductor [typically a grounded - lead from a DC power supply].

The way I interpret that is that your motor power leads should be black. If one leg is grounded at the transformer then it is a neutral and that leg should be white. If it is not grounded then it is not a neutral and should be black. If that leg is switched then the switched conductor is no longer a neutral. Meaning that you use black wires between the contactor and the motor, while upstream of the contactor you use a black and white wire if the leg is is a true neutral and is unfused.

The colors are to signal you that the wire may have a non-ground potential. That is why you would not use a white conductor between the relay and the motor or if the leg is fused.

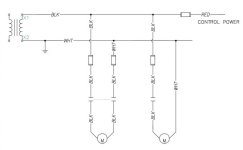

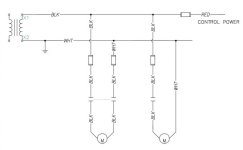

EDIT TO ADD a picture for clarity. Disclaimer, this is not advocating a particular single phase motor control circuit, its just an example of how to select wire colors in different single phase motor control scenarios.