I think @JeremyM is suggesting the PLC should detect the interrupt at the rising edge and to do a minimal amount of processing in the triggered interrupt task routine e.g. increment the base index in the circular array, handle wraparound, and then get out i.e. return.

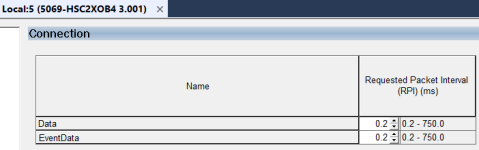

Correct, but he's talking about looking at the HSC "input". The only input on the HSC Card is the encoder pulse train. Even if the input change wasn't bound by RPI, I would presume the A/B channel frequency would exceed the possible event task scan time. Would obviously depend on the frequency of the encoder which I'm not sure was disclosed. That's only assuming the Event Interrupt operated outside the RPI. But it doesn't to my knowledge, so the point is moot.

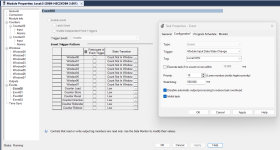

By putting an event task on the HSC encoder input change, it would be equivalent to a 2ms periodic event, as at most the event would only detect a change at the RPI interval. You can set periodic events themselves less than 2ms, so the HSC event task wouldn't gain anything from a speed standpoint. Would gain utilization if the machine wasn't running and the HSC card not changing, but that's all I see as a benefit.